Drying

Drying has a significant share in industrial energy consumption, in many sectors.

Drying has a significant share in industrial energy consumption, in many sectors.

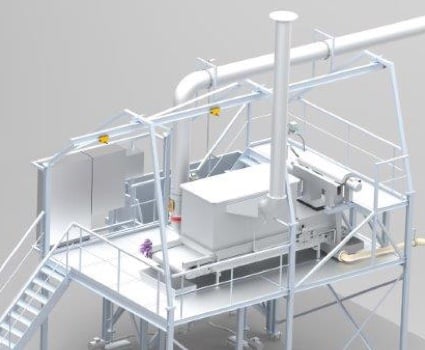

Supported by the Thermolab we create customized, state-of-the-art industrial dryers. For starters, an optimal drying recipe is developed for the specific product. CEE then designs a machine that can impose that recipe perfectly on the product to be dried. Finally we will check how the dryer, integrated on the specific site, can best be supplied with the necessary energy. This can range from waste heat from another production process and/or cooling machines, to for example, CHP-integration.

CEE has already developed and implemented industrial dryers for various applications in various sectors. The following table offers an overview of some typical products treated by our dryers.

Check out our references or send us an e-mail if you have any questions.

The following table offers an overview of some typical products treated by our dryers:

| Bulk | |

|---|---|

| Coffee | Metal Grains |

| Cocoa | Fibreglass |

| Sand | Wood chips |

| Barley | Digestate |

| Malt | Gelatine |

| (Non-)Organic sludge | Wood chips |

| Solid Recovered Fuels (SRF) | Milk powder |

| Polypropylene | Clay pebbles |

| Flax | Lucerne |

| Non-Bulk | |

|---|---|

| Bricks | Gypsum Blocks |

| Fiber cement panels | Concrete products |

| Coatings | Textile |

| Drywall | Paper |