Roasting installation – CO2 free roasting

Customer Request

Worldwide CO2 emissions from the coffee industry amount to no less than 60 million tons per year!

Innovation in Thermal Production Processes to achieve minimal CO2 emissions is the core businesses of CEE. This is the type of mission we often realize for our customers. Often the only possible solution is to invent and realize a completely new process.

Our founder, Koen Bosmans, presented CEE with the challenge to develop an efficient and CO2 neutral roasting process with the following main requirements:

- Minimal temperatures yet maximum quality

- Minimal energy consumption

- Electrification of the process

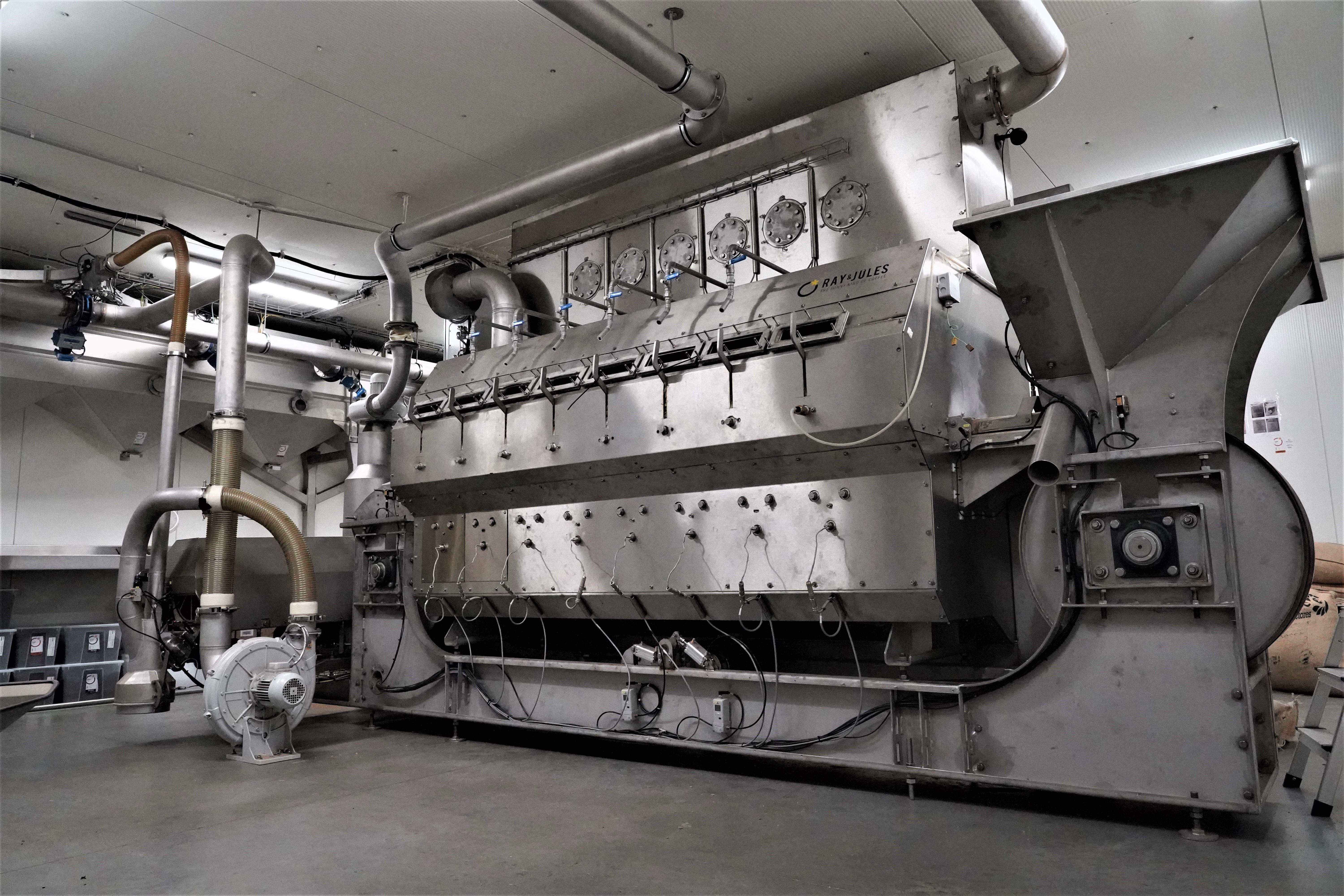

CEE developed and built the coffee roaster. Today it is operated by its sister company Ray & Jules : www.ray-jules.com , solar roasted coffee.

Approach

The temperature to which the beans are exposed was measured In a classic batch drum roaster. This recipe was reproduced in the CEE Thermolab whilst measuring the internal temperature of the beans . As a consequence, recipes were reduced from 6 minutes with a peak of 450°C to 12 minutes and a maximum of 220°C: both energy saving and a better retention of the aromas!

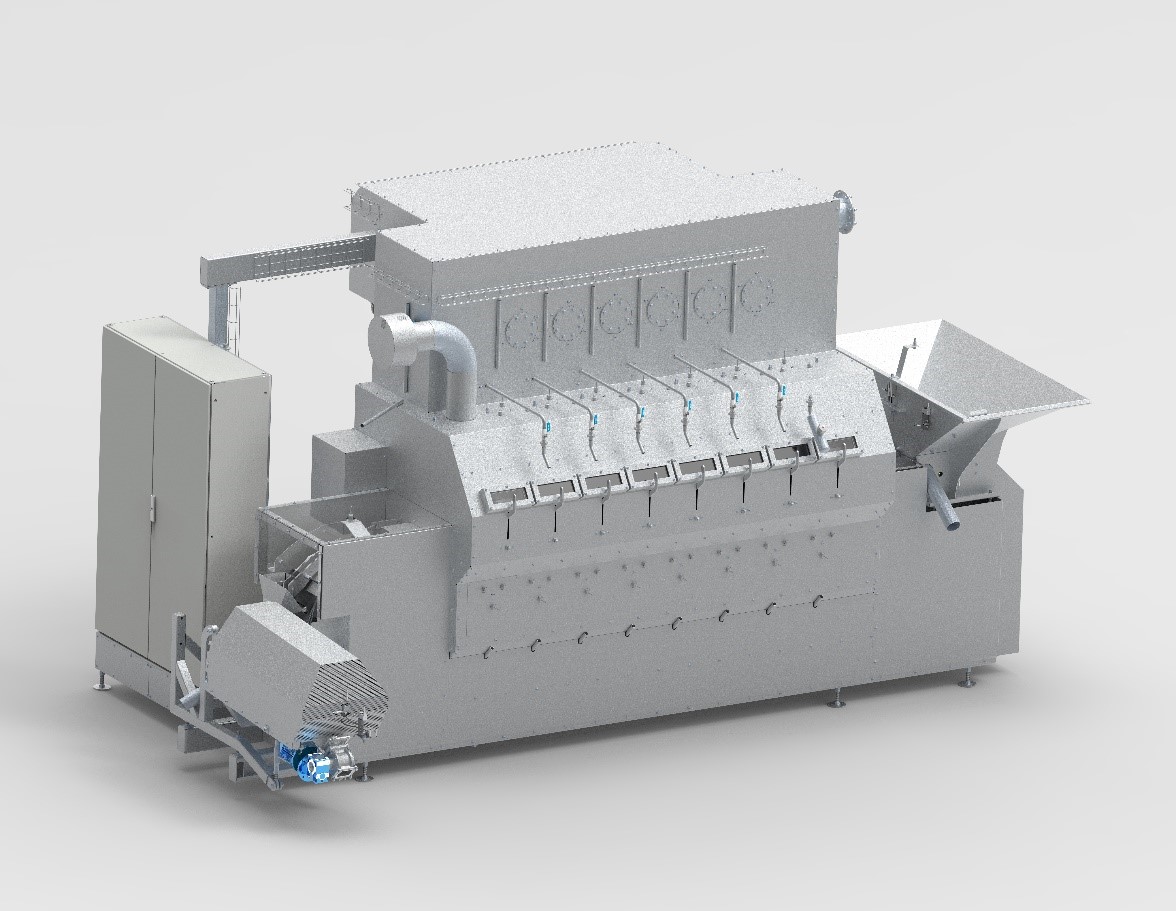

The roasting installation was designed and built by CEE on the basis of a totally innovative concept: a continuous process instead of a batch roaster with 8 independent treatment zones.

3D design of the Roasting installation

Result

The installation contains all necessary elements and features:

- A perforated stainless steel belt transports the beans through the roaster

- 8 independently controlled and measured treatment zones

- Treatment time from 12 to 24 minutes

- Throughput up to 2000 kg/hr

- Temperatures from 80°C to 250°C.

- Energy consumption 3 times inferior to a classic batch roasting process

- A limited power that allows roasting exclusively on electrical energy, CO2 free

- Limited and continuous air emissions

- Final cooling with air instead of water, for aroma preservation and energy saving

- Dehulling the roasted beans in a drum with extraction through a cyclone filter.