Customer request

Implementation of a Measure proposed by CEE during an Energy Audit.

Result

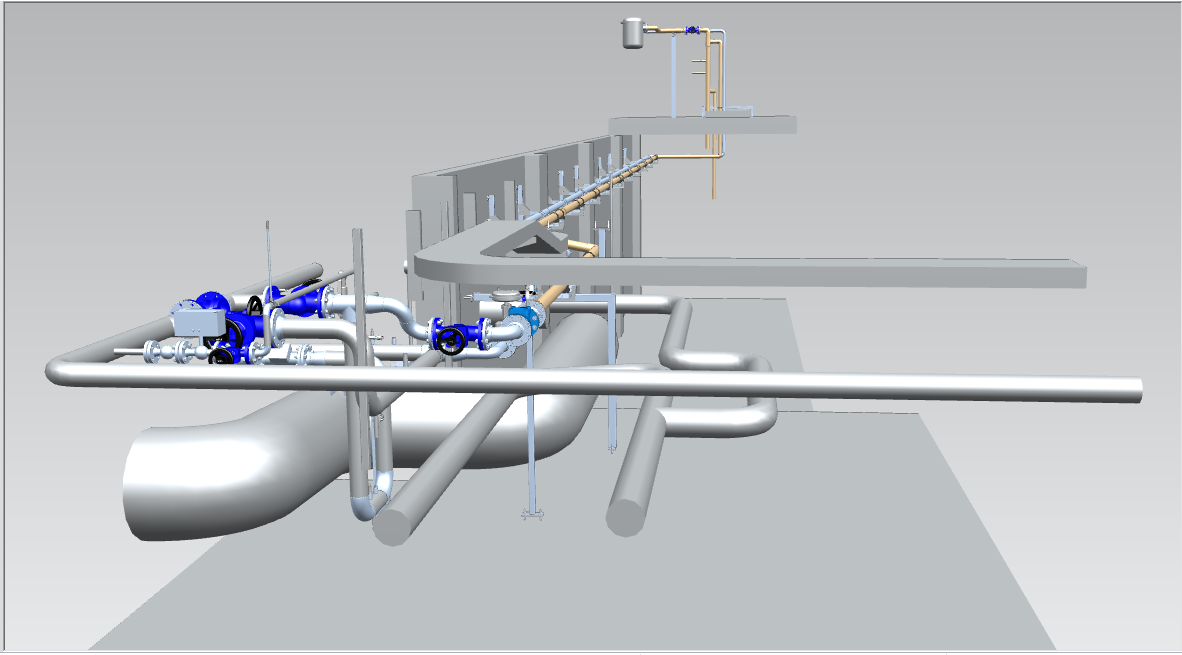

The hydraulic integration of the Condensor, part of the modern Steam Plant at PB Gelatins resulted in maximum energy recovery from the steam boiler exhaust gases, cooling these to 60°C.