Barry Callebaut UK: Heat cold balancing in industrial utilities

Customer request

CEE was entrusted with a project for Barry Callebaut in the United Kingdom for the implementation of a high-efficiency energy installation for heat and cold production and distribution. This new installation is designed to serve the energy consumers on the plant site in an optimal way and consequently to reduce the customer's carbon footprint.

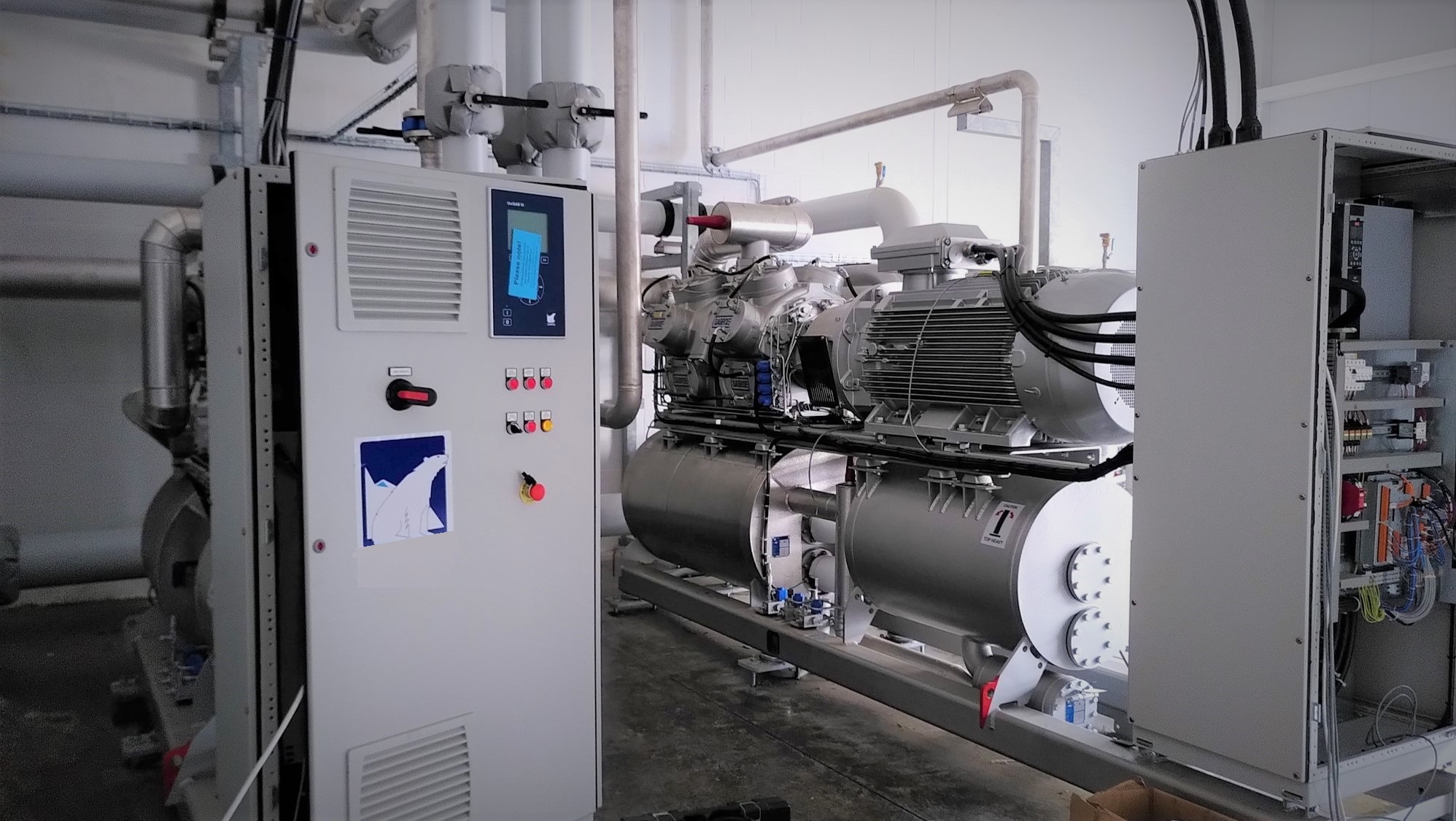

The site is equipped with an industrial heat pump. The coupling between the cooling water system and the hot water system provides 2 useful energy flows produced by a single machine. This technology will aid the customer to deliver on his carbon targets.

Approach

The design was perfectly prepared in advance through a combination of 3D scanning of the as-is situation and 3D design, allowing to reduce the construction time to as little as 6 weeks.

Result

Turn-key project with the following components:

Installed cooling capacity of 2.5 MW_th through an NH3 heat pump, an NH3 compressor chiller and an adiabatic cooler

Installed heating capacity of +/- 1 MW_th through a natural gas-fired hot water boiler and an NH3 heat pump

Thermally layered buffer capacity with a total buffer volume of 85 m³ at various temperature levels

Distribution of heat and cold via +/- 1.5 km piping in stainless steel 304L in diameters varying between DN20 and DN200

Full pipe rack for all new outdoor setups

Full in-house electrical design

Full in-house programming

Start-up planned around the end of 2020

Follow-up during the warranty period